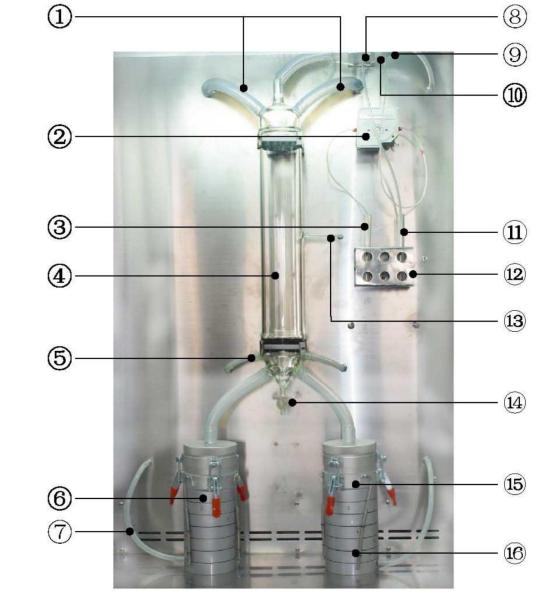

Face mask test equipment

ASTM EN standard face masks virus penetration test equipment for protect

- Operating temperature :(0~50)℃

- Cabinet negative pressure: (-50~-200)Pa

- Total number of positive QC sampler particles :(2200 ± 500) cfu

- Negative pressure cabinet door size :(L1000×W730)mm

- Product description:ASTM EN standard face masks virus penetration test equipment for protect

Application:

The main performance indicators of the mask bacterial filtration efficiency (BFE) tester not only meet the requirements of the B.1.1.1.1 test instrument of the B. BFE test method in Appendix B of Medical Surgical Mask Technical Requirements HY0469-2011. The American Society for Testing Materials ASTMF2100. ASTMF210K European EN14683 standard requirements, and based on this innovative improvement, the use of dual gas path simultaneous sampling method to improve the accuracy of sampling, suitable for metrological inspection departments, research institute Performance test of mask filter efficiency by the institute, mask manufacturers and other related departments.

|

The main parameters

|

Parameter

|

Resolution

|

Max allowable error

|

|

A sample flow

|

28.3L/min

|

0.1L/min

|

better than±2.5%

|

|

Sampling flow of channel B

|

28.3L/min

|

0.1L/min

|

better than±2.5%

|

|

Spray flow

|

(8~10)L/min

|

0.1L/min

|

better than±5.0%

|

|

Peristaltic pump flow

|

(0.006~3.0)mL/min

|

0.001ml/min

|

better than±2.5%

|

|

Front pressure of channel A

|

(-20~0)kPa

|

0.01kPa

|

better than±2.5%

|

|

B-channel flowmeter front pressure

|

(-20~0)kPa

|

0.01kPa

|

better than±2.5%

|

|

Pressure before spray flowmeter

|

(0~300)kPa

|

0.1kPa

|

better than±2.5%

|

|

Aerosol chamber negative pressure

|

(-90~-120)Pa

|

0.1Pa

|

better than±2.0%

|

|

Operating temperature

|

(0~50)℃

|

||

|

Cabinet negative pressure

|

(-50~-200)Pa

|

||

|

Data storage capacity

|

>100000 group

|

||

|

HEPA filter characteristics

|

Filtration efficiency for particles above 0.3um ≥99.99%

|

||

|

Aerosol generator mass median diameter

|

Average particle diameter (3.0 ± 0.3) μm, geometric standard deviation ≤1.5

|

||

|

Dual 6-stage Anderson sampler captures particle size

|

Grade Ⅰ> 7μm, Grade Ⅱ (4.7 ~ 7) μm, Grade Ⅲ (3.3 ~ 4.7) μm, Grade Ⅳ (2.1 ~ 3.3) μm, Grade Ⅴ (1.1 ~ 2.1) μm, Grade Ⅵ (0.6 ~ 1.1) μm

|

||

|

Aerosol chamber specifications

|

(Length 600 x diameter 85 x thickness 3) mm

|

||

|

Total number of positive QC sampler particles

|

(2200 ± 500) cfu

|

||

|

Negative pressure cabinet ventilation flow

|

≥5m3/min

|

||

|

Negative pressure cabinet door size

|

(L1000×W730)mm

|

||

|

Host size

|

(L1180×W 650×H1300)mm

|

||

|

Bracket size

|

(L1180×W 650×H 600)mm,Height adjustable within 100mm

|

||

|

Working power

|

AC220V±10%,50Hz

|

||

|

Instrument noise

|

<65dB(A)

|

||

|

Total Weight

|

about 350kg

|

||

|

Machine power consumption

|

<1500W

|

||

Categories

Contact

CONTACT USContact:Anna

Phone: +86 14775548318

Email: hns@szhonas.com

Whatsapp: +86-14775548318

Add:805 Jingfa Building, No. 46 Baoqian Lane, Baoqian Road, Baoan District, Shenzhen

Anna

Anna SZ HONAS

SZ HONAS +86-14775548318

+86-14775548318