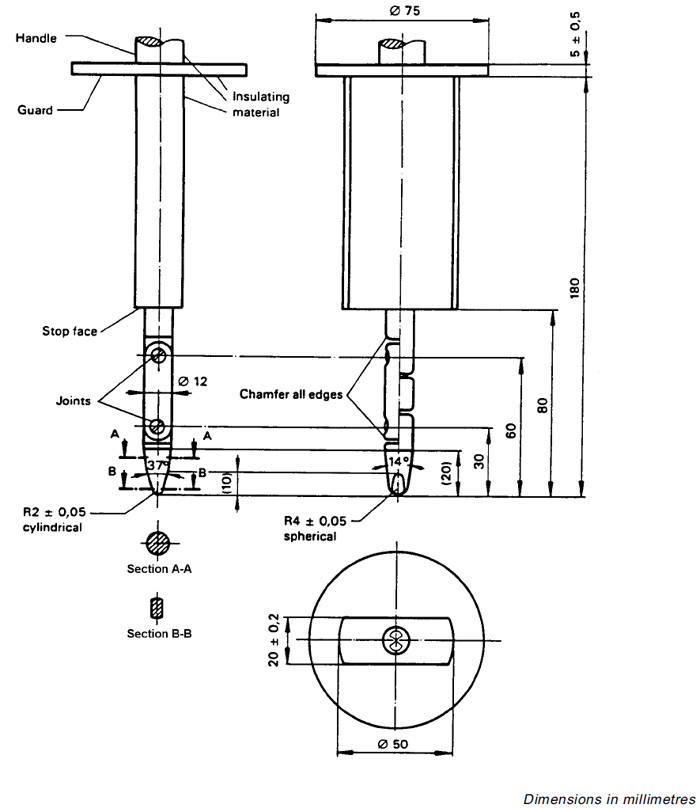

test finger

IEC61032 IP2X standard jointed test finger probe B

- Knurled Finger Length:80mm

- Knurled Finger Diameter:12mm

- Baffle Plate Diameter:100mm

- Materials:metal, except where otherwise specified.

- Product description:IEC61032 IP2X standard jointed test finger probe B

Application:

household and electrical appliance ,protective test for preventing finger touch or electric shock proof.The standard test refers to this jointed finger that simulates a person's finger ,it is consists of a finger, a middle finger, a finger seat, and an insulated handle. Both joints shall permit movement in the same plane and the same direction through an angle of 90° with a 0° to +10° tolerance.

Jointed finger probe is mainly manufactured for testing the protection against access to hazardous parts. It is a high-precision probe, which simulates human finger movement.it can be with 10±3 N force if necessary.

Technical Parameter:

|

Model Number |

HNS-P2B |

|

Knurled Finger Length |

80mm |

|

Knurled Finger Diameter |

|

|

100mm |

|

|

Baffle Thickness |

20mm |

|

Materials |

metal, except where otherwise specified. |

|

on linear dimensions |

up to 25 mm: 0- 0,05 mm; over 25 mm: ± 0,2 mm. |

|

Standard |

IEC61032 Fig2, IEC60950 ,IEC60529 ,IEC60335,IEC60884 |

Customized:

The end of the handle is equipped with a pluggable banana plug and terminal block for electric shock test, or the M6 threaded hole at the end of the handle (used with a push-pull force gauge) for the outer casing protection test.

Instruction:

1.In the standard test, the joint part cannot touch the live parts or the dangerous parts, and the 50mm-20mm baffle cannot enter.

2.In the test requirements to prevent access to hazardous parts, the Type B test probe is required to have a thrust of 30 ± 3 N. Generally used in conjunction with push-pull gauges.

3. In the anti-shock test, it is necessary to connect and configure the power supply and indicating device: determine whether the grounding wire (three plugs), open the power switch of the tested product, and apply the corresponding thrust.

Categories

Contact

CONTACT USContact:Anna

Phone: +86 14775548318

Email: hns@szhonas.com

Whatsapp: +86-14775548318

Add:805 Jingfa Building, No. 46 Baoqian Lane, Baoqian Road, Baoan District, Shenzhen

Anna

Anna SZ HONAS

SZ HONAS +86-14775548318

+86-14775548318