Products

Pharmaceutical product temperature humidity test chamber

- Temperature range 0~65℃

- Temperature fluctuation / uniformity ±0.5℃/±2℃

- Humidity range/deviation 35~95%RH/±3%RH

- Working temperature RT+5~30℃

- Product description:Pharmaceutical product temperature humidity test chamber

1.Sample description:

This test equipment is prohibited:

Testing and storage of samples of flammable, explosive and volatile materials and testing and storage of corrosive substances

Testing or storage of biological samples

Test and storage of strong electromagnetic emission source samples

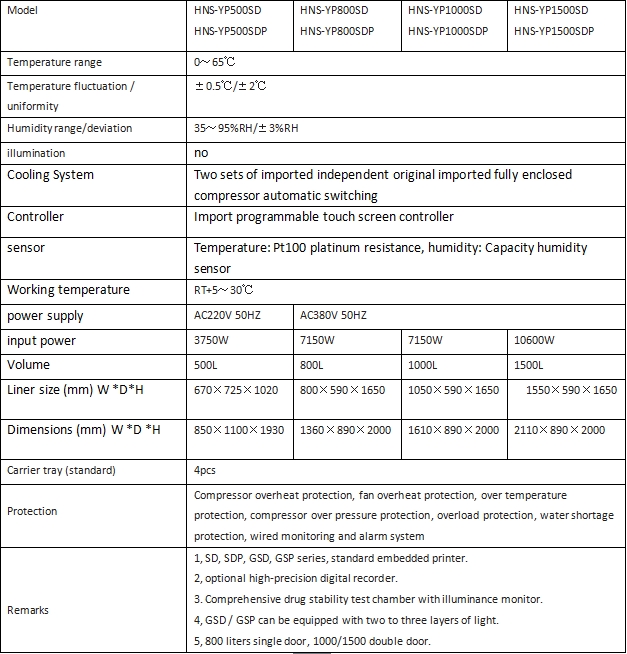

Model

HNS-YP500SD

HNS-YP500SDP

HNS-YP800SD

HNS-YP800SDP

HNS-YP1000SD

HNS-YP1000SDP

HNS-YP1500SD

HNS-YP1500SDP

Temperature range

0~65℃

Temperature fluctuation / uniformity

±0.5℃/±2℃

Humidity range/deviation

35~95%RH/±3%RH

illumination

no

Cooling System

Two sets of imported independent original imported fully enclosed compressor automatic switching

Controller

Import programmable touch screen controller

sensor

Temperature: Pt100 platinum resistance, humidity: Capacity humidity sensor

Working temperature

RT+5~30℃

power supply

AC220V 50HZ

AC380V 50HZ

input power

3750W

7150W

7150W

10600W

Volume

500L

800L

1000L

1500L

Liner size (mm) W *D*H

670×725×1020

800×590×1650

1050×590×1650

1550×590×1650

Dimensions (mm) W *D *H

850×1100×1930

1360×890×2000

1610×890×2000

2110×890×2000

Carrier tray (standard)

4pcs

Protection

Compressor overheat protection, fan overheat protection, over temperature protection, compressor over pressure protection, overload protection, water shortage protection, wired monitoring and alarm system

Remarks

1, SD, SDP, GSD, GSP series, standard embedded printer.

2, optional high-precision digital recorder.

3. Comprehensive drug stability test chamber with illuminance monitor.

4, GSD / GSP can be equipped with two to three layers of light.

5, 800 liters single door, 1000/1500 double door.

Test method

1. High humidity test: 25 °C ± 2.0 °C 90% R. H ± 5% R. H or 25 °C ± 2.0 °C 75% R. H ± 5% R. H (10 days)

2. Accelerated test: 40 ° C ± 2.0 ° C 75% R. H ± 5% R. H or 30 ° C ± 2.0 ° C 65% R. H ± 5% R. H (180 days)

3. Long-term test: 25°C±2.0°C 65%R.H±5%R.H or 30°C±2.0°C 65%R.H±5%R.H (365 days)

4, temperature test point: 40 °C 60 °C

5. Pharmaceutical preparations (large infusions, eye preparations, etc.) packaged in semi-permeable containers

Accelerated test: low humidity test: 40 °C ± 2 °C 25% RH ± 2% RH

Long-term test: 25 °C ± 2 °C 40% ± 5% RH or 30 °C ± 2 °C 35% ± 5%

Conditions of Use The following conditions are guaranteed by the user.

Place

The floor is flat, well ventilated, free of flammable, explosive, corrosive gases and dust

No strong electromagnetic radiation source nearby

Ground bearing capacity of drainage floor drains near the equipment: not less than 800kg/m2

Appropriate maintenance space around the equipment

Environmental conditions

Temperature: 5 ° C ~ 35 ° C

Relative humidity:≤85%RH

Pressure:86~106kpa

Power

AC380V Three-phase four-wire + protective ground wire;

Voltage allowable fluctuation range: AC (1 ± 10%) 380V

Frequency allowable fluctuation range: (1 ± 1%) 50Hz

The grounding resistance of the protective ground wire is less than 5Ω;

Require the user to configure the air or power switch of the corresponding capacity for the device at the installation site, and this switch must

Must be used exclusively for this device

Max power

8KW

Requirements for the storage environment

When the equipment is not working, the temperature of the environment should be kept within 0~35°C.

When the ambient temperature is lower than 0 °C, the water remaining in the equipment should be drained to prevent the water in the pipeline from freezing and rising.

Categories

Contact

CONTACT USContact:Anna

Phone: +86 14775548318

Email: hns@szhonas.com

Whatsapp: +86-14775548318

Add:805 Jingfa Building, No. 46 Baoqian Lane, Baoqian Road, Baoan District, Shenzhen

Anna

Anna SZ HONAS

SZ HONAS +86-14775548318

+86-14775548318